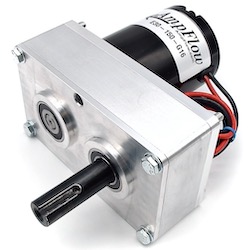

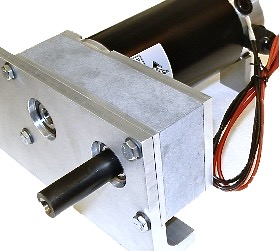

The AmpFlow speed reducers are heavy-duty, low-cost gearheads that work with any of the three-inch diameter AmpFlow motors.

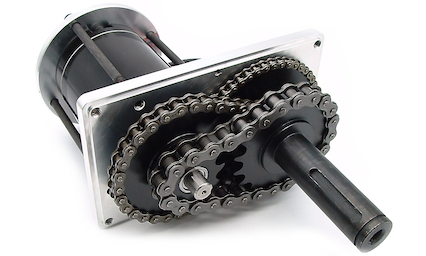

The speed reducers use a unique three-stage chain-and-sprocket mechanism that reduces cost while delivering very high torque capacity.

This unit provides speed reduction and torque multiplication, and it's an easy way to "bolt in" the AmpFlow motors.

Motor voltages range from 6V to 72V, and reduction ratios range from 1:4 to 1:27. Find the perfect combination below, or we can design a custom gearmotor.

Here are some tips for choosing the best reduction ratio.

⇩ Click the tabs to see the different reduction ratios. ⇩

| Type | High-Performance Economy Gearmotors | |||||

| Voltage Range | 6 to 18 Volts | 12 to 36 Volts | 24 to 72 Volts | |||

| Model | E30-400-12-G8 | E30-150-12-G8 | E30-400-24-G8 | E30-150-24-G8 | E30-400-48-G8 | E30-150-48-G8 |

| Nominal Voltage | 12V1 | 12V1 | 24V1 | 24V1 | 48V1 | 48V1 |

| Peak Horsepower | 1.4 | 0.5 | 1.9 | 0.9 | 2.4 | 1.0 |

| Reduction Ratio | 1:8.3 | 1:8.3 | 1:8.3 | 1:8.3 | 1:8.3 | 1:8.3 |

| Stall Torque (in-lbs) | 470 | 200 | 730 | 350 | 900 | 370 |

| No-Load RPM | 750 | 620 | 660 | 640 | 670 | 640 |

| Weight (lbs) | 9.4 | 7.1 | 9.4 | 7.1 | 9.4 | 7.1 |

| Price | $329 | $299 | $329 | $299 | $329 | $299 |

| Pictures |

|

|

|

|

|

|

| Drawings |

|

|

|

|

|

|

| Performance Charts |

|

|

|

|

|

|

| Order | ||||||

⇩ Click the tabs to see the different reduction ratios. ⇩

| Type | High-Performance Gearmotors | Mid-Range Gearmotors | ||

| Model | A28-400-G8 | A28-150-G8 | F30-400-G8 | F30-150-G8 |

| Nominal Voltage | 24V1 | 24V1 | 24V1 | 24V1 |

| Peak Horsepower | 3.9 | 2.7 | 2.3 | 2.1 |

| Reduction Ratio | 1:8.3 | 1:8.3 | 1:8.3 | 1:8.3 |

| Stall Torque (in-lbs) | 1730 | 950 | 1090 | 660 |

| No-Load RPM | 560 | 700 | 520 | 790 |

| Weight (lbs) | 10.5 | 7.4 | 11.9 | 8.1 |

| Price | $669 | $564 | $509 | $459 |

| Pictures |

|

|

|

|

| Drawings |

|

|

|

|

| Performance Charts |

|

|

|

|

| Order | ||||

⇩ Click the tabs to see the different reduction ratios. ⇩

| Type | Fan Cooled High-Performance Gearmotors | |||

| Model | A28-400-F24-G8 | A28-150-F24-G8 | A28-400-F48-G8 | A28-150-F48-G8 |

| Nominal Voltage | 24V1 | 24V1 | 48V1 | 48V1 |

| Peak Horsepower | 3.9 | 2.7 | 10.43 | 4.1 |

| Reduction Ratio | 1:8.3 | 1:8.3 | 1:8.3 | 1:8.3 |

| Stall Torque (in-lbs) | 1730 | 950 | 25202 | 1220 |

| No-Load RPM | 560 | 700 | 740 | 850 |

| Weight (lbs) | 10.6 | 7.5 | 10.8 | 7.6 |

| Price | $719 | $614 | $719 | $614 |

| Pictures |

|

|

|

|

| Drawings |

|

|

|

|

| Performance Charts |

|

|

|

|

| Order | ||||

The fan motors have ventilation holes in the front and rear aluminum plates to allow for flow-through cooling. The holes in the front plate are positioned so they are not blocked when mounting the motor to a flat surface. These motors also feature low-profile motor leads for better fit into smaller spaces.

1 The above specifications are for the motor's nominal voltage. The motors can also be used at lower or higher voltages. The RPM is proportional to the voltage, so running at half the nominal voltage will result in half the speed, and twice the voltage will double the speed. The maximum achievable torque is also proportional to the voltage. Shorter duty cycles are recommended for higher voltages to allow the motors time to cool. Please note that the above torque figures are the theoretical peak torques when stalled. Operating any high-performance motor while stalled will damage it.

2 Maximum torque limited by speed reducer.

3 Theoretical peak power is 10.4 HP. Power at the recommended short-term current limit of 200A is 9.1 HP. The current required to reach this figure is far outside the safe operating limits of this motor. This figure is theoretical and should be used for comparative purposes only.

These speed reducers are made with a three-piece aluminum case that has been precision CNC machined. A total of six sprockets, three roller chains, and five bearings comprise the mechanism. The long output shaft makes it easy to mount pulleys, sprockets, gears, or wheels in the required position. Care was taken to make this unit as compact as possible. The overall thickness of all but the 1:19 reducer is just over two inches. But the motor is recessed slightly into the reducer, so the net length added to the motor is only 1.8 inches.

The speed reducer uses a unique arrangement of roller chains. This results in torque and efficiency comparable to gear-type reducers at just 1/2 or even 1/3 of the cost of high-torque, geared speed reducers. There is slightly more noise, but these units are ideal when silent operation is not required.

Standard Speed Reducers

The output shaft of all but the 1:19 reducer is 3/4-inch in diameter and 2.2 inches long. The 3/4-inch shafts have a 1/4-inch keyway and a 5/16-24 threaded hole. If something other than the 1/4-inch key is required, step key stock is available.

A single stage of roller chain reduction is generally considered to be about 98% efficient. Add in some friction from the five bearings, and we are at about 90% efficiency.

G19ET Extreme Torque Speed Reducer

The 1:19 reducer is designed for higher torque than the other reducers. The first two reduction stages are done with #25 and #35 roller chains. But, unlike the other reducers, a #40 chain is used for the final stage. With a torque capacity of 480 pound-feet, it can handle 60% more torque than the 1:27 reducer.

This reducer has a one-inch output shaft with an integrated sprocket machined from a solid steel billet. The shaft runs in a big two-inch bearing which is pressed into a CNC-machined aluminum plate that is twice as thick as the plates in our standard speed reducers.

In addition to the standard mounting screws, the motor is supported by four 1/4-inch screws running the entire length of the motor. This is helpful in applications that may involve impacts and high g-forces.

Testing

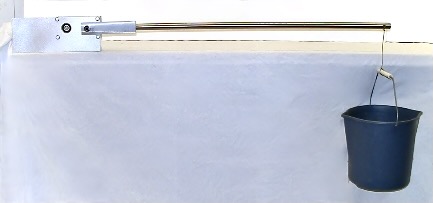

Torque Test

This picture shows the speed reducer undergoing a torque capacity test. The motor is locked and unable to turn. Weight is loaded onto the end of the 40-inch bar until the speed reducer fails.

Based on the advertised tensile strength of the various chains, the calculated torque capacities are:

- 1:4 ratio: 160 pound-feet

- 1:8 ratio: 210 pound-feet

- 1:16 ratio: 270 pound-feet

- 1:19 ratio: 480 pound-feet

- 1:27 ratio: 300 pound-feet

(The actual tested failure points are about 30% higher.)

The failure point is the chain in the final stage of speed reduction. The gearbox suffers no other damage, and the chain is easily replaceable.

Backlash Test

The gearhead is tested for backlash by locking the motor in place. A load of 200 ounce-inches is applied in both clockwise and counterclockwise directions. The total deflection is +/- 1.2 degrees. This figure may increase somewhat with higher loads and chain wear, but replacement chains are available.

Mounting

Four long 1/4-20 bolts go all the way through the width of the reducer. The four mounting bolts are supplied with the unit. They are sufficient in length to mount the gear motor to a 3/8-inch thick panel. If the panel is thicker, longer bolts will be needed. Do not operate the speed reducer with bolts that are missing or too short - they are required for structural integrity.

Replacement parts are available here.

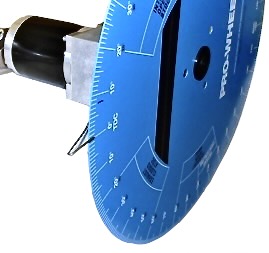

Optical Encoder

Hover to see mounted optical encoder

All our three-inch motors (other than the fan motors) can be supplied with an optical encoder. The encoder mounts on the back of the motor, and it comes with a 20-inch cable. It has 512 PPR and an index. Here is the wiring chart:

| Black | Ground |

| Yellow | Index |

| White | Channel B |

| Red | +5VDC |

| Green | Channel A |

We can mount the encoder, or it can be ordered separately.

Warranty

The gearmotors are warranted to be free from manufacturing defects and fully operational when you receive them. AmpFlow gives no other warranty, either expressed or implied. Warranties are not transferable. In no event shall AmpFlow's liability exceed the buyer's purchase price, nor shall AmpFlow be liable for any indirect or consequential damages.

We accept Visa, MasterCard, and PayPal.

We accept Visa, MasterCard, and PayPal.

Contact us for custom motors and volume pricing: